Highest SOTE available on the market today

Standard Oxygen Transfer Efficiency of 2.8% per foot of depth

This is an entirely new method of aeration. Our Patented Technology transfers so much dissolved Oxygen that in a clean water test we reach maximum saturation in the time it takes to flow only half of the containment. Our process is simple, we draw from one end and inject the water in the other end through our patented Taeration Nozzle. This exclusive Push-Pull system allows for complete circulation and De-Stratification of your containment regardless of shape or depth. Drawing in only ambient air we are capable of air/water ratios as high as 10 to 1 and are achieving this using a fraction of the Horse Power used by all other methods. Retrofitting Industrial Applications with out of the gate energy saving up 70% makes this a long awaited solution for:

|

Pilot Specifications

|

Energy Efficiency (5HP Taeration system)

|

| Nozzle | Motive Flow gal/min |

Motive Flow PSI |

Air Flow FPM Feet / min |

Air Flow GPM gal / min |

Air Flow CPM cubic feet / min |

Air / Water Ratios | Max DO | Time To Max | Time to max saturation 8.6 mg/l |

Aeration Rate GPS | Air Flow to 100% |

| 1/2" AIA | 60.2 | 65 | n/a | 123.42 | 16.5 | 2.05/1 | 9.6 | 3:55 | 1:50 | 3.86 | 30.19 cf |

| 3/4" AIA | 125 | 55 | 740 | 203.95 | 27.26 | 2.63/1 | 9.6 | 2:20 | 1:30 | 6.04 | 49.88 cf |

Oxygen transfer is determined using the ASCE clean water non-steady state test procedures.

| AIA Systems | Operating P.S.I. | Flow Rate Through Nozzle GPD | GPD Mixing Rate | Gallons Mixed Per Hour | lbs. O2 Delivered/Hour | lbs. O2 Transferred/Hour | GSEE Certified SOTE | Kw/H | lbs. O2 Delivered/KwH | lbs. O2 Transferred/KwH |

| 20HP with 4 3/4" Nozzles | 50 | 835,200 | 100m/gpd | 4.17 | 290.80 | 31.98 | 11% | 16.0 | 18.17 | 1.9987 |

| 15HP with 2 3/4" Nozzles | 50 | 417,600 | 50m/gpd | 2.08M | 145.40 | 15.99 | 11% | 12.0 | 12.11 | 1.3321 |

| 5HP with 1 3/4" Nozzle | 50 | 208,800 | 25m/gpd | 1.04M | 72.70 | 8.00 | 11% | 5.0 | 14.54 | 1.6 |

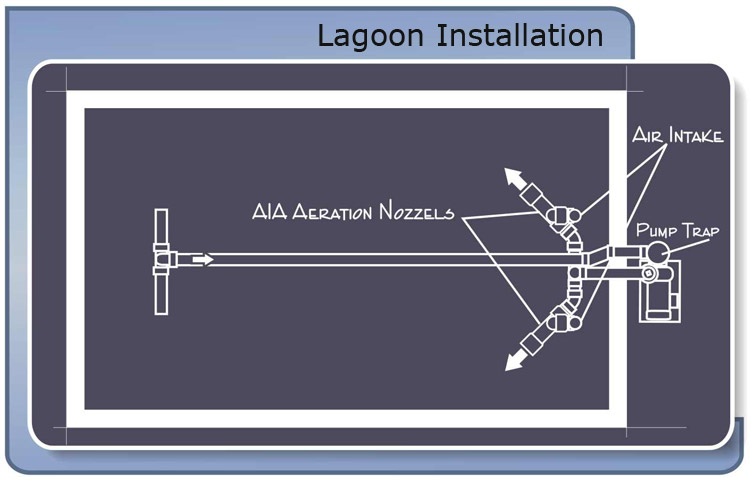

For complete circulation, AIA Aeration systems draw from the deepest part of the containment and the farthest away from the nozzle discharge. This is accomplished by the drawing from one end and discharging at the other. The mixing ability is further enhanced by the amount of air entrained in the nozzle flow. The AIA system is the only system that achieves complete circulation with the least amount of energy required.

Eductors typically have a mixing ratio of 5 to 1, One gallon in and five gallons mixed. AIA's mixing ratio is on the order of 120 to 1 because of the air water ratios induced by the nozzles, ensuring complete de-stratification. When our system is properly sized, as soon as all the water in containment has flowed through the nozzle ONE time, you can visually see a current flowing throughout the ENTIRE containment.