Fine Bubble Taeration for CAFO

More Dissolved Oxygen, Less Energy, and Superior Mixing

|

“The Taeration fine bubble system for CAFO, played a dramatic part in reducing nutrient levels. When the farm tripled its daily process flow there was enough oxygen available to have peak nutrient reductions of 87%.”

Neil Beckingham - QED |

Pilot Specifications

|

Energy Efficiency (20 HP Taeration System)

|

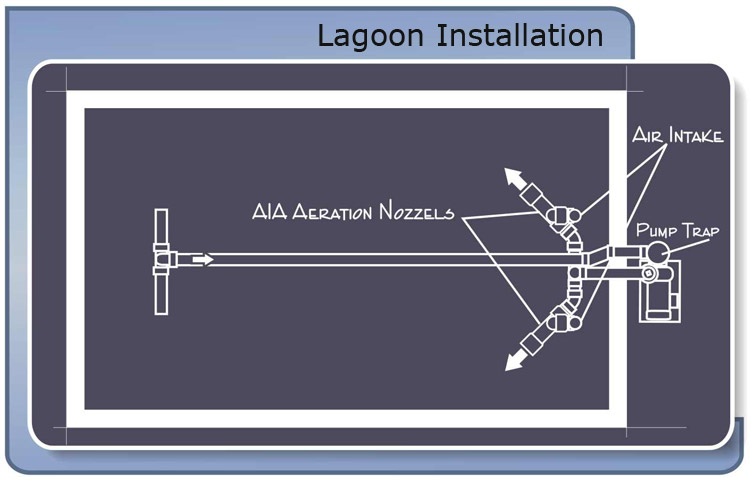

In July 2005 the Farm Pilot Project Coordination, Inc (FPPC) granted QED Environmental Services LLC (QED) partial funding (43%) for a pilot plant (PP) at the Dairy Production Systems (DPS) dairy in Florida USA. QED chose two 20HP Taeration Systems for their fine bubble aeration in their Biological System.

The FPPC is a US government funded entity established to select and fund technologies that have the potential to significantly reduce the pollution of farmlands and waterways from the discharge of effluents from concentrated animal farming operations (CAFO’s).

The objective of the FPPC funding is for the funding recipient to demonstrate the viability of their technology in a real farm application. As a result the documentation and verification of the treatment process and treatment results is of key importance to the project. Other key criteria for the project includes the farmers commitment to the long term viability of the treatment system and that the technology provides a complete solution for the wastes produced, i.e. by products from the treatment process having a commercial value to end product users.

The key objective of the contract is to demonstrate the viability of the QED multi stage separation technology as a low cost sustainable technology for the removal of nutrients from dairy farming effluent. Specifically the aim of the plant was to remove 75% P & N.

The DPS - Branford dairy is permitted by Florida Department of Environmental Protection (FDEP) to milk 2,050 cows on a 3 milking per day, 7 day per week basis. The farm occupies 593 owned acres and an additional 103 adjacent rented acres and borders on the Sante Fe River. As such nutrients leaching into the river are closely monitored with 11 bores along the riverbanks sampling the quality of water seeping into the river.

The project involves the supply of a complete effluent treatment system (ETS) required to treat a minimum of 100,000 gpd of effluent and to reduce the level of P and N in the effluent by 75%. The contractual obligation is to treat 100,000gpd, however, the farm currently uses 300,000gpd, so the intention was to design the main vessel to have a capacity of up to 300,000gpd to accommodate a higher flow rate if necessary.

The key client criterion for the contract was to demonstrate the economic viability of removing substantial quantities of nutrients (primarily P, N) from the effluent. This was achieved by:

- supplying a fit for purpose, cost (capital) effective system

- providing a system that has an appropriate operating cost, including:

- i) minimum chemical usage to achieved desired water quality

- ii) low energy consumption

- iii) minimum number of operating items of equipment, there by reducing maintenance costs, and

- iv) has low as practical requirement for farm labor intervention.

- providing a robust system that requires minimum technical support

- ensuring that the system consistently removes agreed quantity of nutrients from the effluent

- ensuring that the solids produced are in a form ready for composting (15-20% dry matter) and in-turn commercial sale, there by providing a revenue stream to offset operating cost

- providing sampling points to monitor effluent, and

- provide substantive reports to document the performance of the system.

Complete system TN reduction (physical-chemical and biological combined) was able to achieve a peak reduction of TN of 88% (meeting plant criteria).

The peak TP total system reduction is 87% (meeting plant criteria).

Complete system TS reduction (physical-chemical and biological combined) after flush system installed currently averages ~68%

Despite doubling the incoming nutrient concentrations the total system was able to achieve a peak performance of 87% Total Phosphorous (TP) reduction and 88% TN reduction, exceeding the project success criteria. The total system is currently achieving averaged reductions of 68% Total Phosphorous (TP), 61% TN, 68% Total Solids (TS) and significant odor reductions. It is predicted the ASBS would also significantly reduce pathogens with an up to 10°F temperature increase across the system due to biological activity. Flow rate of the TFS is 220,000gpd, over double the pilot rate.

| TKN | Total Phosphate | TS |

| 61% | 68% | 68% |

View the full report (pdf)