Aeration, Mixing, and De-Gassing all with one energy source

Aeration

With the highest transfer rate per ft. of depth (2.8%) our technology transfers more of what the EPA defines as a "micro-bubble" than any other method available today. In fact in a clean water test we reach maximum saturation of the entire containment after re-circulating only half of the containment through our Taeration nozzle regardless of its shape or depth. More O2 results in higher densities and faster growth rates.

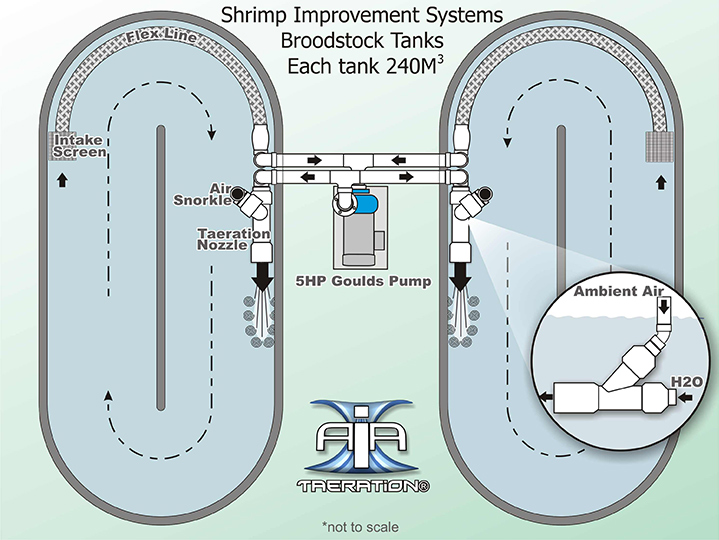

Mixing and Circulation

Drawing water from one end and injecting it back into the opposite end ensures proper circulation and disbursement of the O2 throughout. Crucial in a Bio-Floc system we mix 120 Gallons for each single gallon that passes through our Taeration nozzle. This not only creates great water flow or tank velocity, but also keeps the floc in suspension eliminating problematic ammonia pockets.

De-Gassing

Our Taeration technology injects air and water at a ratio averaging of 3 to 1. For each gallon of water that flows through the nozzle, 3 gallons of air are entrained and injected out the exit cylinder. Often overlooked and rarely tested for this high ratio de-gasses CO2 and other noxious gasses from the water. A fishes respiratory rate is governed by O2, however, increased co2 levels in the water will reduce the rate at which CO2 is released from the blood through the gills. This can lead to not only stunted growth rates, but disease as well.

Injection Point

Our Non-Venturi naturally aspirating system is capable of pulling a near absolute vacuum, providing a perfect injection point for Ozone or pure oxygen.

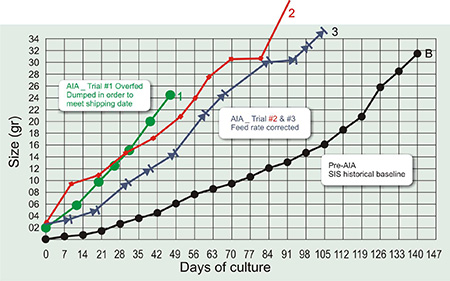

In Shrimp Improvement System's broodstock tank we used less horsepower, increased the stocking density by 25%, and grew the shrimp twice as fast, with survival rates exceeding 90%.

|

Actual CP-2 Data - Stocked 5/27/2008 with ~20,000 Juveniles at 2g

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

*Harvested the entire pond on 7/17/2008 with a total of 17,381 animals (9,354 males and 8,027 females) |

USING A NON-VENTURI AIR INJECTION SYSTEM TO RAISE Litopenaeus vannamei IN A HIGH DENSITY BIO-FLOC SYSTEM

World aquaculture Association conference Veracruz Mexico ‘09

The Importance of Measuring Carbon Dioxide in Aquaculture

MOTE marine laboratory uses Taeration technology in their wastewater percolation pond.

USDA’s Harbor Branch Research Facility is using our technology to research fine protein removal using a foam fractionators/ protein skimmer.